6000 series aluminum alloy has magnesium and silicone as the major alloying elements, and Mg2Si is the main strengthening phase. This series alloy can be strengthened by heat treatment. The remarkable properties are moderate strength, good corrosion resistance, excellent welding property and stress-corrosion cracking resistance, good formability and machinability. The alloys containing Cu have similar strength with 2000 series alloys, but worse corrosion resistance. 6061 and 6063 are the most widely used alloys of 6000 series, which have the best comprehensive performance and economy.

6000 series aluminum alloy is used in automotive industry (e.g., window and door parts), architectural applications, hardware, furniture parts, rings, fuses, electrical conductors, screw machine parts, etc.

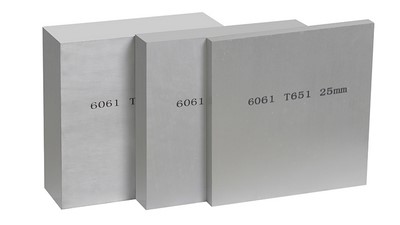

6061 aluminum alloy is the most commonly specified aluminum for general-purpose applications, such as engineering and structural applications, boats (e.g., marine frames), furniture and transportation equipment, electronic parts, architectural applications.

Read More

6082 aluminum alloy is typically used in high stressed applications, beams and trusses, forged pieces, transport applications, bridges, machining parts, shippbuilding, cranes, ore skips, milk churns, etc.

Read More

6063 aluminum alloy is commonly referred as to architectural aluminum, and is used in piping, tubing, general extrusions for medical, automotive, parts profiling and more, architectural products, building & construction extrusions, etc.

Read More

6016/6022 aluminum alloy is widely used in automotive industry for car body, closure panels, etc.

Read More

6101 aluminum alloy serves as a high-strength aluminum material for buses, electrical conductors and radiator materials, aluminum alloy parts of busbar conductor, etc.

Read More

To pack the aluminum sheet/plate/coil, first of all, put a layer of plastic film with a thickness of no less than 0.08mm in the packing box, then a layer of EPE foam, the third layer of PE kraft paper, and finally put the desiccant.